History, Perfected in Scale.

Masterfully Crafted

Authentic Detailing

Engineered for Flight

Historically Accurate

The legend reborn, not just remembered

Engineered for Precision

1:48 Scale Fidelity

Intricately Molded Components

Historically Accurate Details

Developed for Authentic Flight

The Soyuz isn’t just a rocket, it’s a symbol of humanity’s enduring journey into space. This model lets you bring that history to life on your workbench and in the sky.

A Closer Look at Excellence

Every Moment, Considered

Building the Soyuz is just the beginning.

The real magic is watching it take flight for the first time.

Every Detail, Realized

Inside the Design

The Russian space rockets have always fascinated me. I remember being in 7th or 8th grade and walking to our public library on the way home from school. They had a book there that dealt with space flight. In this book were artist created images of several Russian space rockets including the Soyuz. It was the first time I really every seen or read anything about Russian Space Craft. Remember, this was nearly 50 years ago when the Internet didn’t exist, and basic information was hard to come by let alone from behind the Iron Curtain.

Around 10 years ago I came across this very same book, it now resides in my home library and just last week I re-read the section of Russian space flight.

A couple years ago I was asked by Estes Management; if I had one scale model to choose from, to create a scale model for Estes, what would it be? I instantly said Soyuz. They agreed, a scale size was chosen, and off I went with designing my first test model.

This would actually be my second attempt at building a Soyuz model. The first one was started over thirty years ago, was three and half times larger, having a six-inch diameter center stage and powered by a K motor. Stuff happened during the build; and I ended up throwing it all in the garbage.

As a scale model rocket, the Soyuz needed to look good but also fly; this presented many challenges. There would need to be a balance between form and function in this kit’s design. How much detail could I add to the model, what would the cost be for the tooling needed to create these details, but more importantly the model needed to be easy to build and light enough to fly with our largest 29mm F15 engine.

Quite frankly when the final tooling costs came back, I thought for sure this project would be killed but as you can see, the project continued on.

A boiler plate model is the first thing created for any Estes scale model. This is a model that is the size and shape needed to represent the model but most often lacks all the final details of the final kit presented to the public.

It only took a couple weeks to create the parts in Auto Cad for this boiler plate model. They lacked all details and took much more work to assemble than the final kit does, but it served its purpose well. All the plastic parts were 3D in PLA filament.

Based on the balance point of my boiler plate model I knew from the start I was going to have to add a set of clear plastic fins to stabilize my model. The model was assembled and test flown. With a couple of successful flights, the work on the final kit parts could proceed.

I did something I had never done before at Estes; I asked for a tool to be created for one of the blow molded parts. In this case the tool was for the four strap-on boosters. Normally, we get a final tool and parts cost for the entire kit before a final decision is made to actually proceed with new tooling.

The Soyuz was such an important model that a tool was created so I could build additional flight models using at least one real final part that I felt was a key component to this model.

The next important and actually the most important part on this model is the interstage Ferry Struss. This is the open structure part made out of steel sections on the real model. In the case of the boiler plate model, I simply 3D printed one in PLA plastic. It held up just fine during flight testing, but a molded part would be needed for the kit.

To create a tooled molded plastic part of this section of the model turned out to be almost impossible, since the modeler would end up with a bunch a small-sections, that needed to be glued together. My basic design criteria is; If I would not like to do something, in this case construct a critical part out of a dozen smaller parts, the modeler would most likely feel the same way.

The final solution to this issue was to create a one-piece resin printed part out of ABS plastic. I believe this is the first resin printed part to be included in an Estes kit.

I believe the final kit has a good compromise in its included detailed parts, buildability and flight performance. Since the launch lugs are removeable the model can be displayed looking like a miniature copy of the real one and my hope is that plastic model builders will add this 1/48 scale model to their collection.

The Details That Matter

F15-4

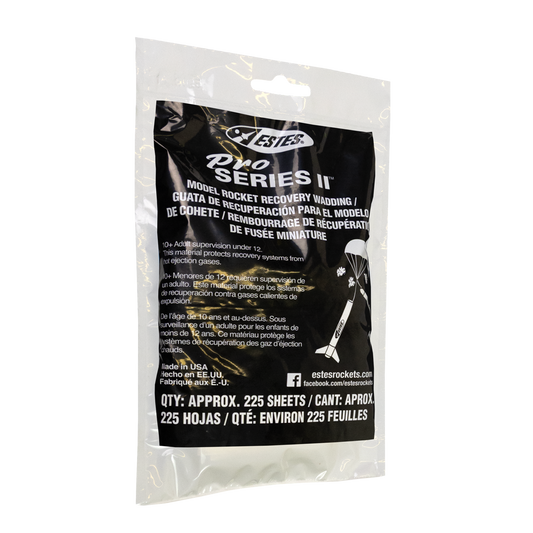

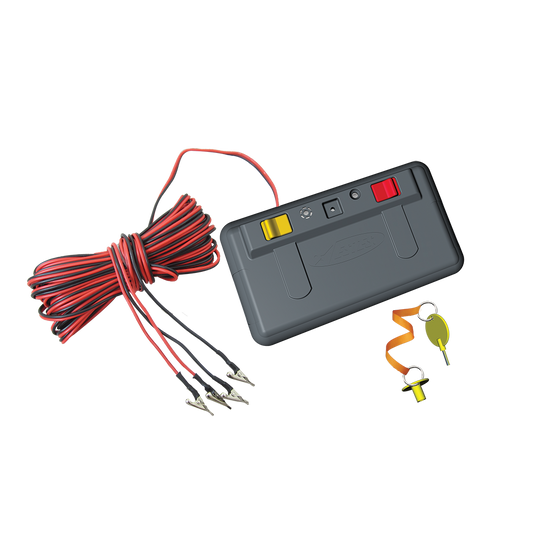

Pro Series II™ Launch Pad

1/4 in. (6.35 mm)

500 ft. (152 m) on F15-4

41.3 in. (104.9 cm)

6.4 in. (16.3 cm)

18 oz. (510 g)

Molded Plastic

18 & 24 in. Rip Stop Parachutes