Push the Boundaries of What a Rocket Can Be

The Pro Series II™ Scorpio 3D is more than a model rocket—it’s your personal design lab. With a unique blend of high-flying performance and total customization, this intermediate-level kit lets you 3D print your own parts and experiment with multiple fin configurations. Whether you’re testing aerodynamic performance or flexing your maker skills, Scorpio 3D gives you the tools to explore rocketry in a whole new way.

Everything You Need—Ready to Print

After purchase, you'll receive access to downloadable 3D print files in both standard and metric units. The printable parts include the nose cone, fin can, body tube coupler, male and female engine retainers, and six distinct tail fin designs. Print them at home using your preferred materials and settings, then get ready to assemble and launch. No special supports are required, and general printer settings are provided to ensure successful prints.

Six Fin Styles. Unlimited Experiments.

The Scorpio 3D’s twist-lock fin can makes it easy to swap fins without tools or adhesives. With six tail fin styles to choose from—or remix and reprint your own—you can explore how different fin shapes impact altitude, stability, and flight behavior. Each launch becomes a chance to test a new theory, compare results, and fine-tune your rocket’s design for your next mission.

Launch Performance Meets Maker Flexibility

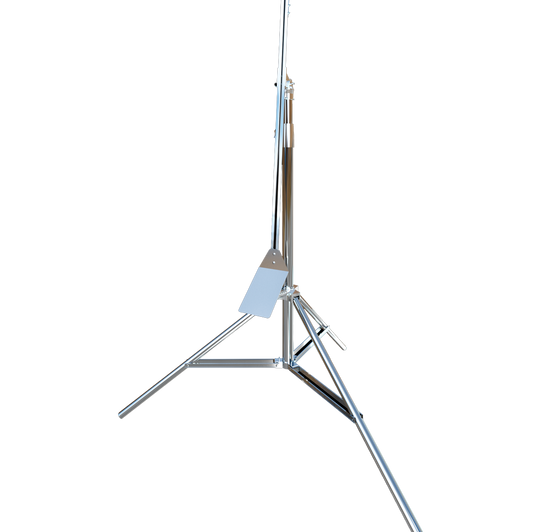

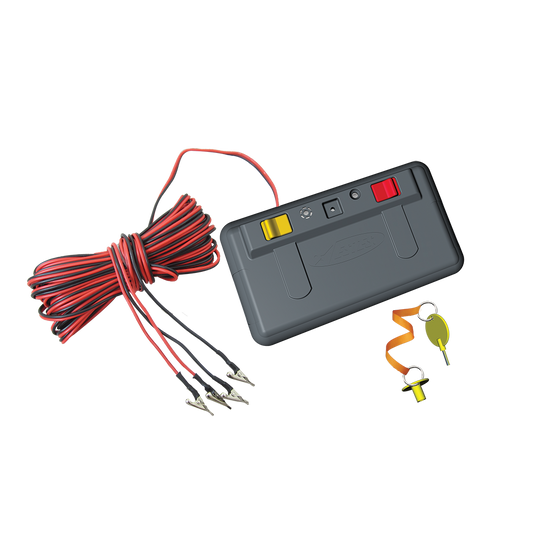

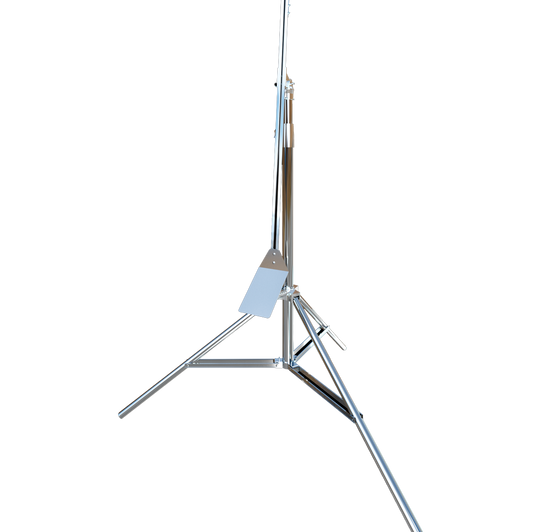

This customizable rocket stands 41.5 inches tall, has a 2-inch diameter, and weighs approximately 17 oz. With an included 24-inch ripstop parachute for recovery and support for E16-4 and F15-6 engines, Scorpio 3D can reach up to 1,000 feet. It’s compatible with both 1/4 inch launch rods and 1010 rails, making it an ideal match for the Pro Series II™ Launch Pad or Launch Rail.

What’s Included in the Kit

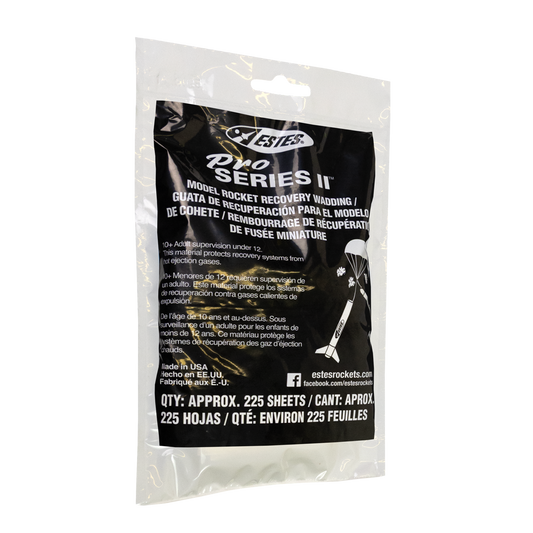

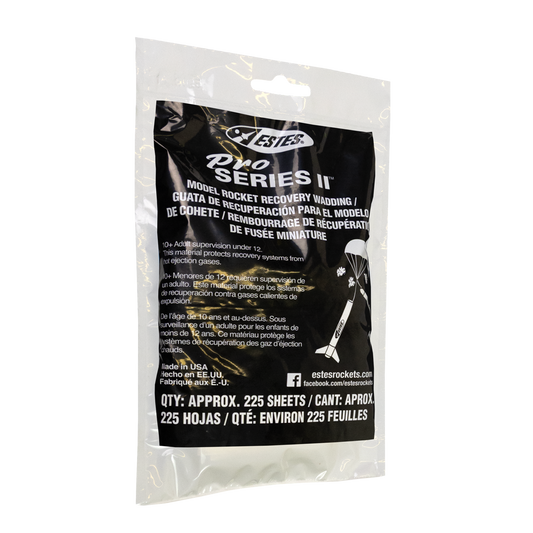

In addition to the downloadable 3D print files, the Scorpio 3D kit includes all the physical components you need to complete your build: a durable body tube, engine mount tube, aramid cord, shock cord, a 24-inch ripstop parachute for recovery, and a set of water slide decals for finishing. These components pair with your printed parts to create a high-performance, fully functional model rocket ready for flight.

Recommended 3D Print Settings

To get the best performance from your printed components, we recommend the following settings: PLA+, PETG, or ABS filaments; no supports required (optional at your discretion); wall thickness of 3 lines with a 0.4 mm nozzle; 7% infill (gyroid); and a 3 mm or wider brim for strong bed adhesion. Once printed, your parts are ready to assemble, fly, and experiment—again and again.

3D Printer Size Requirements

To print the nose cone in a single piece, your 3D printer must have a build height of at least 260 mm. If your printer doesn’t meet this requirement, the nose cone can still be printed in multiple sections and glued together. This alternative method works well but does require a bit more precision and model-building experience to ensure a clean final result.

**A 3D printer is required to use this product; 3D printer sold separately.**

By purchasing this product, you agree to the terms of a limited-use license for the included 3D print files. These files are provided for personal, non-commercial use only. Redistribution, resale, uploading, or sharing of the digital files in any form—whether publicly or privately—is strictly prohibited and constitutes a violation of Estes’ copyright and license agreement.

Unauthorized distribution may result in legal action. Estes reserves all rights to enforce intellectual property protections as allowed by law.

Best Seller

Best Seller Sold out

Sold out Best Seller

Best Seller Best Seller

Best Seller